C.E. Electronics Acoustics Group - CQuiet Traction Elevator System 5 Point Noise Treatment provides a one stop solution for traction elevator system airborne and vibration noise reduction.

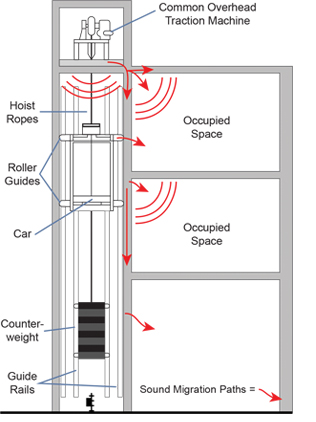

Generating both airborne and structural vibration noise, a traction systems many components; motor brake, gears, electronic control systems, etc., each contribute to the overall noise level intensity and its migration through the building structure.

Our CQuiet Control Products provide effective solutions for the reductions in both airborne and structure-borne sound migration.

Regardless of traction system type; geared, gearless, MRL, the fundamental sound control principles remain the same.

Airborne sound must be contained within the operating environment; motor room or hoistway, while reducing the overall sound level intensity.

Structure-borne sound requires isolation of the source equipment and related components from the building structure. Equipment type and location may introduce factors that can limit the available treatment options.

Building design and construction may be a contributing factor to equipment noise disturbance. Penthouse traction systems generate the highest amount of disturbance complaints.

In what should be the quietest location of the building; penthouse residence of premium commercial office space, these space direct building elements with occupied spaces. The motor room floor is the shared ceiling of the residence, the executive board room is directly adjacent the elevator hoistway.

Side mount systems, basement overhead, MRL and other non-traditional overhead systems add additional complexity to an effective sound treatment. The most effective sound control treatment is one that is planned during the new construction, modernizations, and interior build outs.

C.E. Electronics - Acoustic Group is the only company dedicated to sound control solutions for elevator equipment and their operating environments. Our foundation is architectural acoustics and industrial sound control; coupled with our experience base of the elevator industries equipment, codes, and standards, gives you the most qualifies source to discuss and resolve your elevator equipment.

The CQuiet Noise Control Product line has solutions to address your most difficult traction installations.

.jpg)

For A Free Consultation regarding solutions for your project, call 419.633.3178

Request your Traction Elevator Noise Survey Guide at This email address is being protected from spambots. You need JavaScript enabled to view it.

Sign Up for Newsletter, Product Announcement and Updates

Product Profile

CQuiet Rope Noise Boot Stops Noise And Assures International Building Code Compliance

.jpg)

The recently patented CQuiet Rope Noise Boot not only blocks machine room sounds from entering the hoistway, it meets and exceeds compliance of IBC - International Building Code Chapter 30 Elevators and Conveying Systems - Section 3004 Hoistway Venting: 3004.2 Location of vents. Vents shall be located at the top the hoistway and shall open either directly to the outer air or through noncombustible ducts to the outer air. Noncombustible ducts shall be permitted to pass through the elevator machine room, provided that portions of the ducts located outside the hoistway or machine room are enclosed by construction having not less than the fire-resistance rating required for the hoistway. Holes in the machine room floors for the passage of ropes, cables or other moving elevator equipment shall be limited as not to provide greater than 2 inches (51 mm) of clearance on all sides.

Code Explanation*:

The vent location is intended to aid in the exhaust of smoke to the exterior of the building and to limit migration of smoke into the machine room. At one time, hoistways were vented into the machine room, and a grate in the machine room floor vented to the exterior of the building. Allowing smoke and heat into the machine room may cause equipment malfunction. Therefore, vents must be located in the hoistway directly below the ceiling, and if ventilation through the machine room is advantageous by design, it must be provided through the use of noncombustible ductwork. Further, when noncombustible ductwork is utilized for the ventilation system, any portion of the ductwork that is outside of the hoistway or the machine room must be enclosed by fire-resistance-rated construction equivalent to that required for the hoistway. The clearance around elevator ropes and other moving equipment is limited in size in order to limit the passage of smoke into the machine room.

*Source: International Building Code 2009 Commentaries IBC Link

Sign Up for Newsletter, Product Announcement and Updates